Model: LM-850

Size: 1450*900*1050mm

Power: 6kw

Voltage: 380V50Hz

Capacity: 200-300kg

Machine Weight: 150kg

The small grain grinder, also known as the Self-priming grain crusher, is a

small self-priming crusher with posho mill. The tooth claw grinder is suitable

for grinding corn, beans, cereals and wheat.

Fish feed grain mills are often used as part of a production line for the

crushing and grinding of feed raw materials

The fllowing is the great operation feedback from our customer.

This is a small fish feed pellet production line, and it includes Model 60

fish feed extruder, ish feed ginder and ish feed mixer.

Features of Fish feed grain mills :

1. Small size, space saving, easy to install and fix

2. The grain machine has good adaptability and can be ground, sorghum, corn

stover, peanuts, etc.

3. Reasonable structure, compact structure and convenient maintenance.

4. The operation is simple, no need to fix the foundation, and it is

convenient for the process operation.

Self-priming grain crusher machine running principle:

The high-speed rotating sprocket rotor produces a powerful centrifugal force

that feeds the material into the crushing chamber.

The Self-Priming Crusher uses a positive pressure, high-speed rotating rotor

to generate a large centrifugal force, and the raw material is sucked into the

pulverizing chamber to be pulverized.

Model : LM-40~LM-350

Motor(kw): 2.2KW~22kw

Spindle speed(r/min): 2900~4600

Output: 80-200kg/h~900-2000kg/h

Weight(kg):90kg~680kg

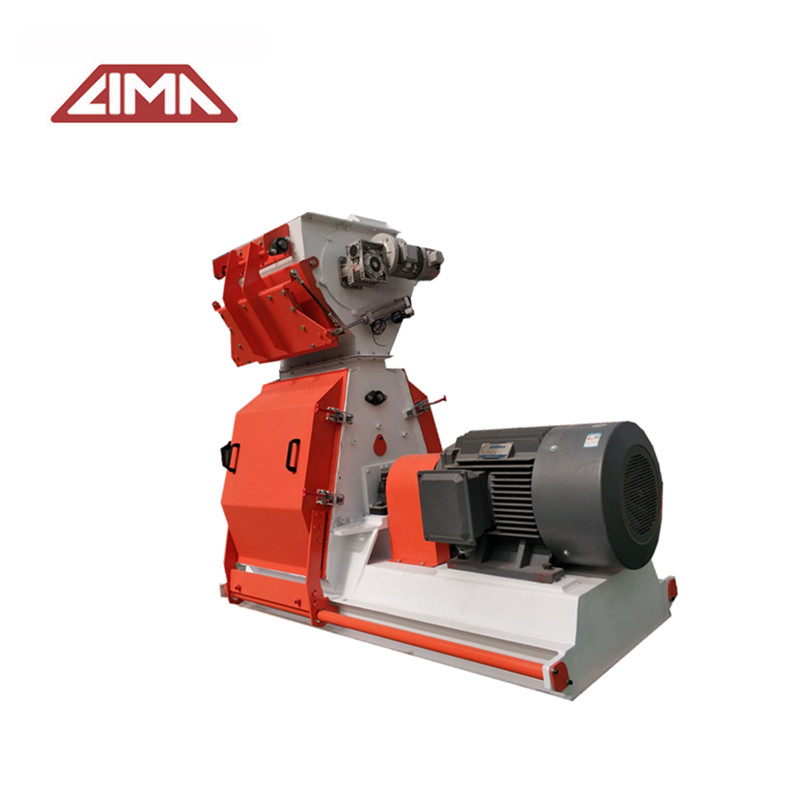

ITEM NAME: LM-32C~LM-35C

Motor power(kw): 22/30~90/110

Production Capacity: 1-2t/h~5-15t/h

Hammer Quantity: 30pcs~90pcs

Screen Quantity: Screen 2PCS, high yield, high grinding efficiency

Screen Hole Diameter: 1,5,2,4,6,8,10,12mm

Rotor Diameter(mm): 560~660

Crushing Chamber Width: 320·800

Mainshaft Speed(rpm):2970

Hammer of Line Speed(m/s):98~105.8

Bearing Number:2312~2218

Screen Size(mm):840*270*2,712*395*2,850*618*2,850*795*2

Anti-vibration Pad: 4~6

Carbon Steel Shell Thinkness: 6mm~10mm

Diamension(L*W*H): 1410*720*970mm,1550*860*1130mm,1900*900*1250mm,2500*1100*1350mm

Weight(Ton):0.8~2