Self-priming toothed disc crusher is a small, multi-purpose, new type of crusher that can crush all kinds of food, medicine, and seasoning raw materials. The machine has wide application, it’s wide used for pharmaceutical industry, chemical industry foodstuff industry, grain industry and so on.

Self-priming toothed disc crusher structure features

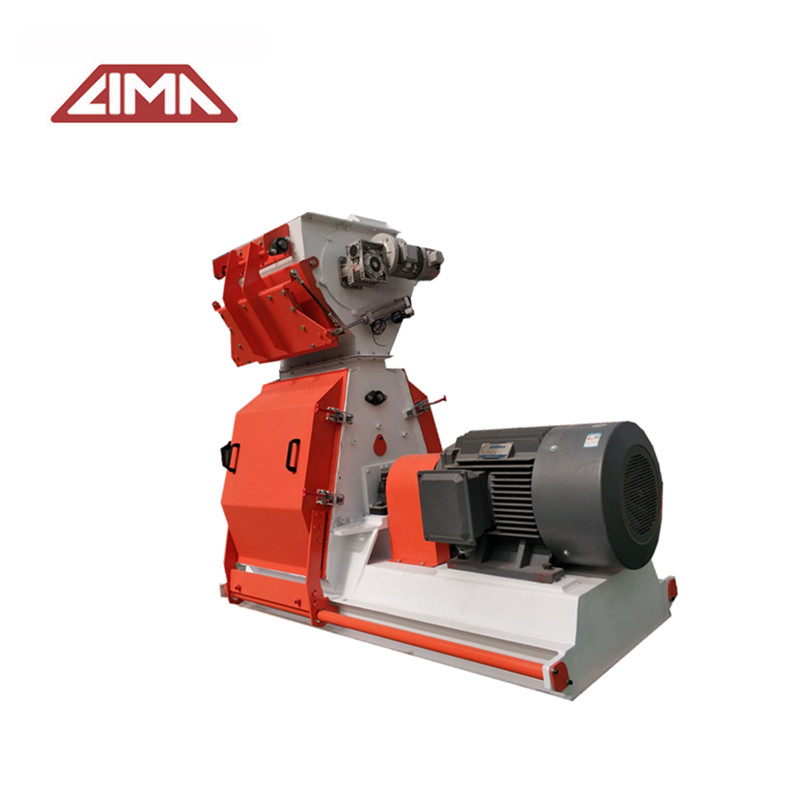

The self-suction type toothed disc crusher has compact structure, beautiful appearance, small size, light weight, reliable use, convenient maintenance, wide application range, high crushing output, and good energy saving, and can well meet customer needs. It is especially desirable to use the machine to process various kinds of miscellaneous grains and feeds such as corn, soybean, sorghum, dried potato, bean cake, etc. After the raw materials are put into the whole, the whole powder is pulverized once, leaving no residue. This machine can also be used to crush a variety of chemical raw materials, paper pulping, Chinese herbal processing and processing of gypsum powder, fish bone powder, metal calcium.

1. Self-priming toothed disc crusher is a small, multi-purpose, new type of crusher that can crush all kinds of food, medicine, and seasoning raw materials.

2. Suitable for the majority of urban and rural units and household food processing, feed processing, medicinal materials processing, seasoning products processing and other professional processing.

3. Different sizes of sieves can be installed according to the needs, and materials with different thickness can be processed.

4. The movement has two types of claw type and hammer type for users to choose.

Features:

1.It can be used for multi-purpose smashing. The device has a dust suction device and no dust pollution. It has the advantages of low noise and high efficiency.

2. The machine has advanced design, reasonable structure, reliable performance, convenient use and maintenance, low power consumption, small floor space and high production efficiency.

3. The toothed disc crusher has small volume, high efficiency, convenient operation and maintenance, simple process configuration, low power consumption, built-in rotor, no dead angle, and more uniform particle size.

4.The body is inlaid and sealed to completely avoid dust spillage and clean working environment.Can be used for ordinary pulverization, fine powder and fine pulverization.

5. The Grain Crusher has a long history of reliable use and is constructed using materials that will last a lifetime.

Model : LM-40~LM-350

Motor(kw): 2.2KW~22kw

Spindle speed(r/min): 2900~4600

Output: 80-200kg/h~900-2000kg/h

Weight(kg):90kg~680kg

ITEM NAME: LM-32C~LM-35C

Motor power(kw): 22/30~90/110

Production Capacity: 1-2t/h~5-15t/h

Hammer Quantity: 30pcs~90pcs

Screen Quantity: Screen 2PCS, high yield, high grinding efficiency

Screen Hole Diameter: 1,5,2,4,6,8,10,12mm

Rotor Diameter(mm): 560~660

Crushing Chamber Width: 320·800

Mainshaft Speed(rpm):2970

Hammer of Line Speed(m/s):98~105.8

Bearing Number:2312~2218

Screen Size(mm):840*270*2,712*395*2,850*618*2,850*795*2

Anti-vibration Pad: 4~6

Carbon Steel Shell Thinkness: 6mm~10mm

Diamension(L*W*H): 1410*720*970mm,1550*860*1130mm,1900*900*1250mm,2500*1100*1350mm

Weight(Ton):0.8~2